Healthcare

Your product and development partner

The healthcare industry is incredibly technology-focused and is subject to numerous regulatory requirements. High-quality technology and reliable laboratory equipment are the basis for quick and accurate diagnoses.

We provide smart products and technologies for the healthcare industry. SERTO components and systems can be found in medical diagnosis systems, treatment systems, laboratory equipment and medical technology. The range of applications extends from analysers to bioreactors and sterilisers. Many years of experience in system design and optimisation coupled with comprehensive expertise in (bio)pharmaceutical standards and processes make SERTO your perfect product and development partner.

Case stories from customers in the healthcare industry

Sartorius Stedim Systems GmbH

“SERTO also supports us in optimising our processes. In this way, we have been able to reduce assembly times with jointly developed assemblies and also reduce assembly costs. We would certainly recommend SERTO as a competent and reliable partner.”

VWR International srl

“We are incredibly satisfied with the new Pinocchio. Because it is made entirely of stainless steel, we can now meet the needs of our pharmaceutical customers, who want an easy-to-clean, disinfectant-resistant unit. Thanks to SERTO’s involvement, we were not only able to make a product completely out of stainless steel, but we also had the opportunity to make it more compact and functional.”

Melag oHG Medizintechnik

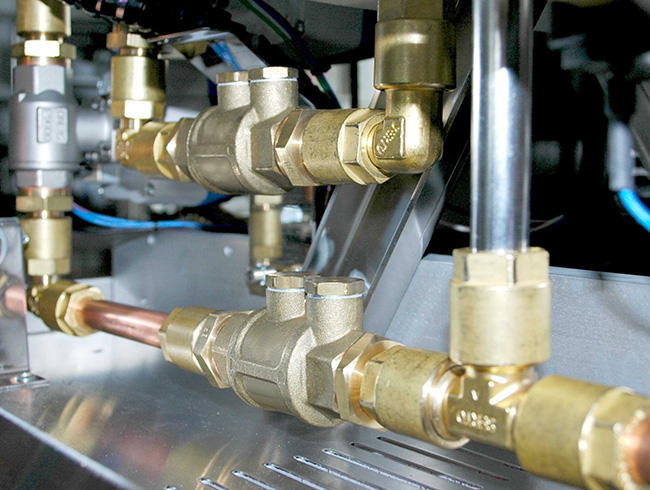

“Due to the radial dismantling option and the high product quality, SERTO unions are among our first choice when it comes to providing a wide range of media supply solutions.”

CONSARCTIC GmbH

“For more than 40 years, our technicians and customers have appreciated the particularly simple and convenient assembly of SERTO unions, especially when compared to other compression ferrule union systems. With SERTO, we can assemble more easily and more quickly, and save up to 40% more time. In addition, radial SERTO unions considerably reduce the effort required when fitting piping, as no compensating bends are required.”

Wesemann GmbH

“The close cooperation and proximity to the customer led us to achieve the special requirements placed on us in this project with SERTO. Implementation involved a special solution on both sides.”

Discover the wide range of our products and the variety of our materials

- Electropolished tubes and flow loops for fine internal surfaces

- Smooth surfaces

- Clean in place (CIP)

- Lubricant-free

- OX applications for oxygen use

Product Highlights

Industry-specific approvals and confirmations

- Food and Drug Administration (FDA)

- USP class VI

Services

System solutions

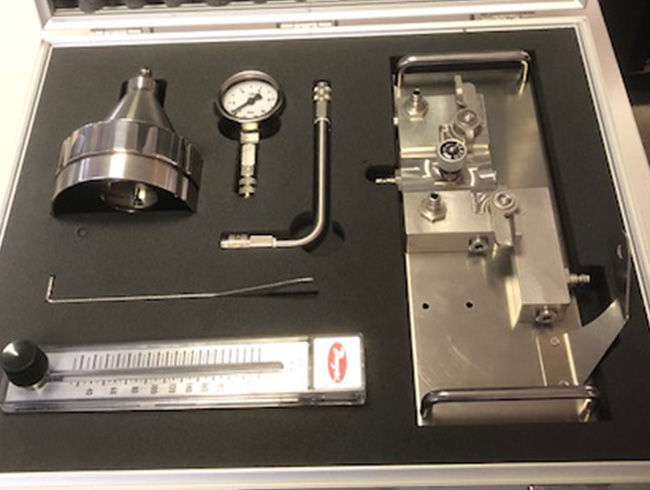

Ready-to-install tubing and kits

We produce over 150,000 metres of metal tubes – every single year! We bend and press the majority of these with unions, valves, ball valves or couplings from the SERTO range.

Bending tubes

When it comes to bending tubes, SERTO has fully automatic, CNC-controlled bending machines that are optimally equipped for diameter ranges of up to 60 mm and an operating radius of six metres.

We also provide...

- Batch traceability: 3.1 certificates

- Customised testing equipment (helium leakage test, bending fatigue strength, flow, vibration, burst pressure, climate and much more)

- Orbital welding: Welding takes place automatically under supply of shielding gas with residual oxygen measurement. This ensures pipes and entire assemblies are welded to the highest quality

Industry expertise

You can rely on our product and material skills!

Our experts can provide targeted support ...

- with comprehensive expertise in (bio)pharmaceutical standards

and processes - in selecting suitable products, materials and processing steps

- in developing tailored systems that meet your requirements

- in managing and coordinating your system project, from the

initial idea through to series production