High-tech

Your product and development partner

The high-tech industry is incredibly focused on technology and producing high-tech components is subject to the strictest manufacturing standards. The high pressure to innovate and the rapid pace of innovation are characteristic of cutting-edge technology.

We support product innovation in the high-tech sector with smart products and technologies. SERTO components and systems are supplied to the semiconductor industry and to manufacturers of lasers and analysis equipment. Many years of experience in system design and optimisation coupled with comprehensive services such as the cleaning system and clean room make SERTO your perfect product and development partner.

Case stories from customers in the high-tech industry

CERN

“We chose SERTO connectors because of their reliability – especially their tightness –, their small size and, last but not least, their ease of use.”

Discover the wide range of products and variety of materials

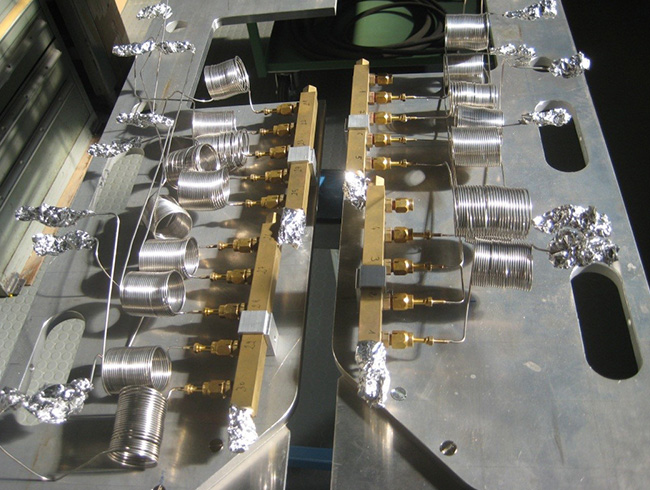

- High purity – ISO Class 8 clean room

- Electropolished tubes and flow loops for fine internal surfaces

- Tube bending instead of welding: more cost-effective, flow-optimised, no dead space and less susceptible to corrosion

- Lubricant-free

Product Highlights

Industry-specific approvals and confirmations

- ISO Class 8 clean room

- Product purity in accordance with ASTM G93 (Level B)

Services

Cleaning

Assemblies

System solutions

We also provide...

- Batch traceability – 3.1 certificates

- Tube bending, welding, cleaning and assembly

- Orbital welding

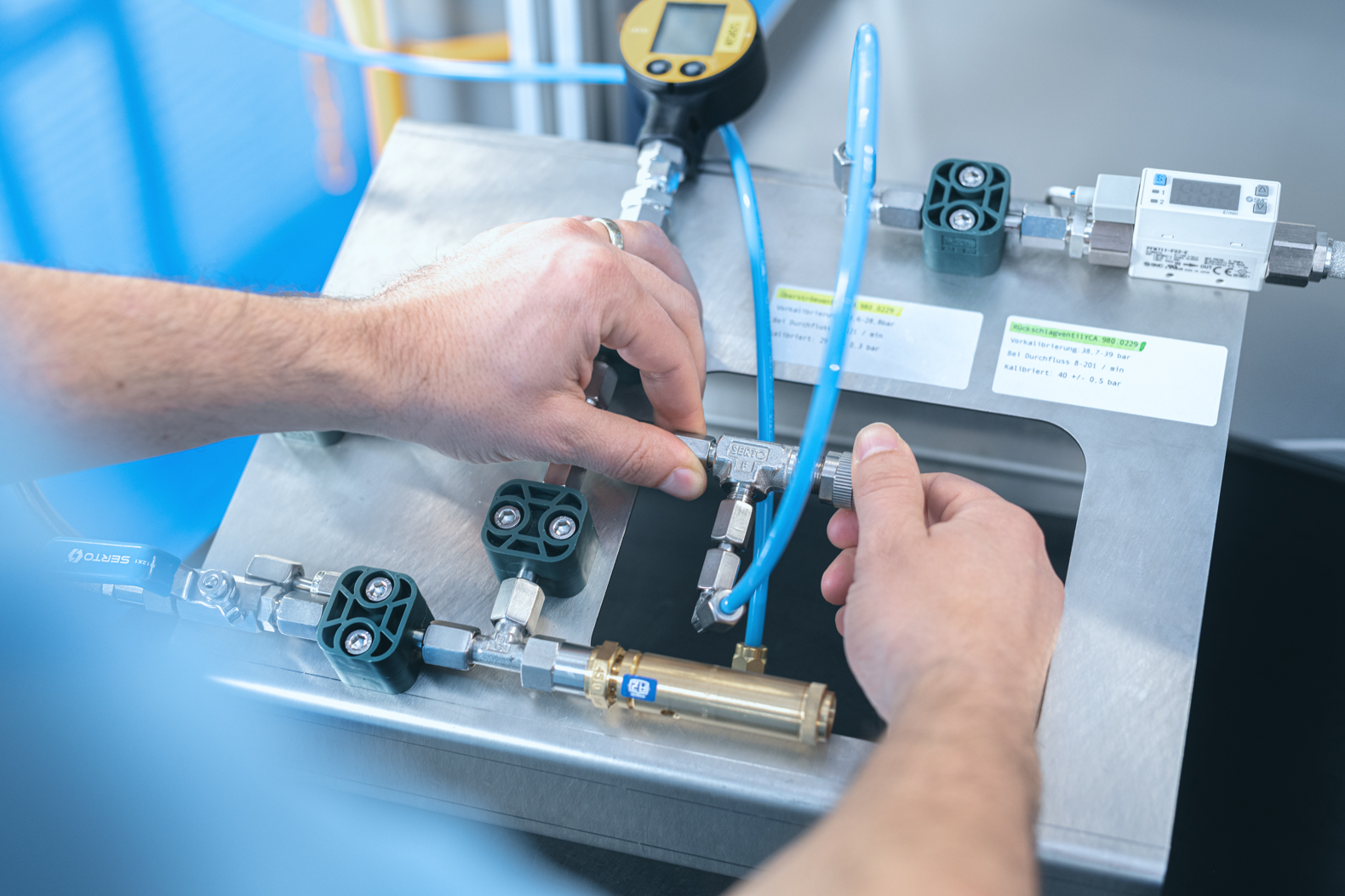

- Customised testing equipment (helium leakage test, bending fatigue strength, flow, vibration, burst pressure, climate and much more)

Industry expertise and know-how

You can rely on our product and material skills!

Our experts can provide targeted support ...

- in selecting suitable products, materials and processing steps

- in supplying and assembling ready-to-use assemblies – even for small batch sizes

- in developing tailored applications and system projects with our extensive expertise

in core technologies